INDUSTRIES

Medical

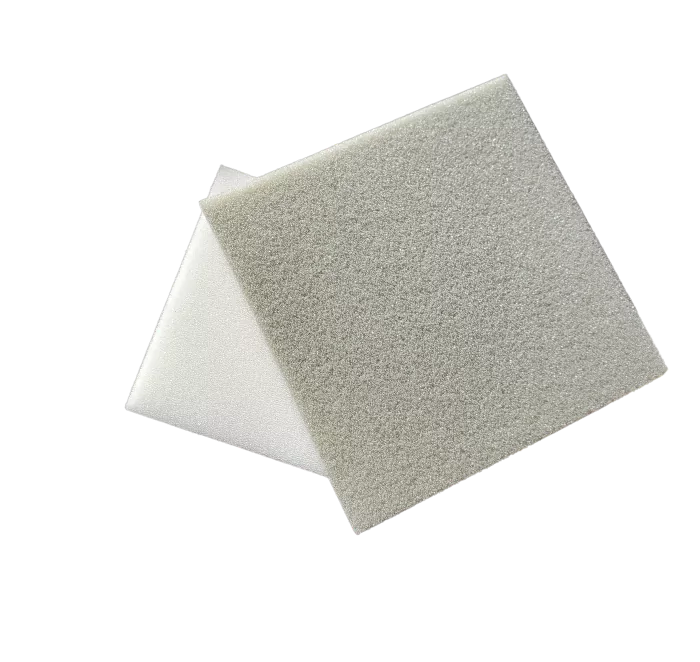

Leveraging a global network of innovators, scientists, and engineers we provide reticulated and non-reticulated polyurethane medical foam products designed to meet the highest standards of quality and function required to serve the medical community. Our extensive global production network offers efficient delivery.

Woodbridge INOAC medical foams are processed using specific manufacturing techniques to ensure a quality product with each lot. Using our advanced processing capabilities, the foams can be provided in multiple formats including bun stock, rolled goods and die cut shapes. Our in-house lamination allows for the development of multi layered composites using foams and fabrics. Our standard medical foams have been tested to meet ISO 10993 biocompatibility standards. Select from our standard foams or contact us to discuss a specific application.

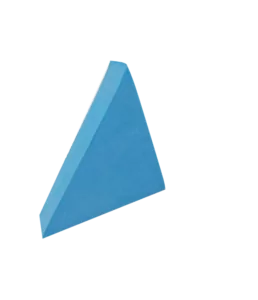

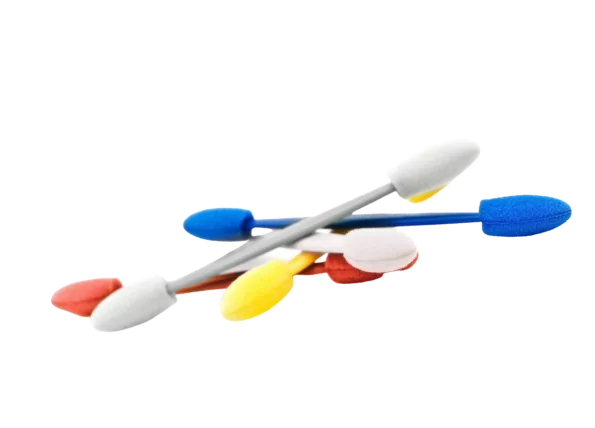

Aiding in patient care with unique foam solutions including foam wedge positioners, ventilator air filtration, gaskets, instrument protection kits, negative pressure wound care and others.